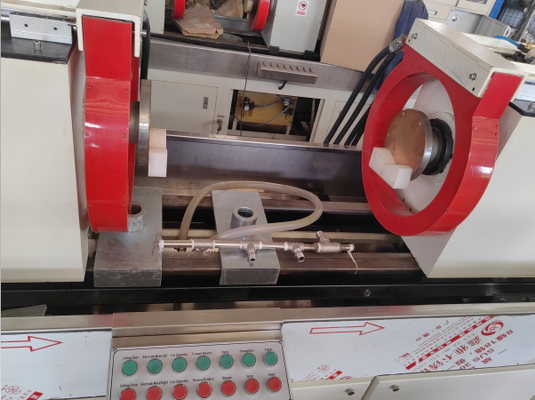

Floresan manyetik partikül çatlak bulma makinesiHMP-8000

1. Çalışma prensibi

Manyetik partikül denetimi, manyetik sızıntı alanı ile iş parçasının kusurundaki manyetik toz arasındaki etkileşimi kullanır. Demir ve çelik ürünlerin (çatlaklar, cüruf inklüzyonları, kılcal çizgiler vb. gibi) yüzey ve yüzeye yakın kusurlarının geçirgenliği ile demir ve çelik geçirgenliği arasındaki farktan yararlanır. Manyetize edildikten sonra, bu malzemelerin süreksiz yerlerindeki manyetik alan bozulacak, manyetik akı sızıntısının bir kısmını oluşturacak ve manyetik sızıntı alanına neden olacaktır. Böylece manyetik tozu kusurda - manyetik izde - birikmeye çeker, uygun aydınlatma koşullarında, kusurun yerini ve şeklini gösterir.

2. Kullanım

Floresan manyetik partikül çatlak bulma makinesi, dövme, su verme, taşlama, yorulma nedeniyle oluşan çatlaklar ve cüruf inklüzyonları ve diğer ince kusurlar nedeniyle ferromanyetik iş parçasının (örneğin: dişli, dişli halkası, dişli mili vb.) yüzeyini ve yüzeye yakınını tespit etmek için kullanılır.

3. Teknik parametre

Algılama aralığı:Dişli çapı≤700mm,yükseklik≤410mm;

Eksenel çap≤300mm,Uzunluk<700mm

Elektrot aralığı:0~410mm(ayarlanabilir)

Çevresel akım:AC 0~8000A Etkin değer(Kesinti faz kontrolörü ile)

Boyuna manyetik potansiyel:AC 0~18000AT Etkin değer(Kesinti faz kontrolörü ile)

Algılama yöntemi: floresan manyetik partikül denetimi

Manyetizasyon modu: çevresel manyetizasyon, boyuna manyetizasyon, kompozit manyetizasyon

Sıkıştırma modu: pnömatik sıkıştırma

Demanyetizasyon etkisi: artık manyetizma 0.3mT'den az

Algılama hassasiyeti: A1 standart test filmi (15/50) açıkça görüntülenir

Güç kaynağı: üç fazlı beş telli AC 380V 50Hz

4. Elektrik parçalarının ana markası ve tedarikçisi

Ekipmanın tüm bileşenleri ve parçaları ithal veya yerli ünlü marka ürünleridir, ev yapımı ürünler kalite testinden geçmiştir.

|

Hayır

|

Adı

|

Marka

|

Miktar

|

Birim

|

|

01

|

Buton anahtarı/gösterge

|

DELIXI

|

1

|

SET

|

|

02

|

Minyatür devre kesici

|

DELIXI

|

1

|

SET

|

|

03

|

AC kontaktör

|

DELIXI

|

1

|

SET

|

|

04

|

PLC

|

OMRON

|

1

|

SET

|

|

05

|

Dokunmatik ekran

|

WEINVIEW

|

1

|

SET

|

|

06

|

Pnömatik eleman

|

DELIXI

|

1

|

SET

|

|

07

|

Tristör tetikleme kartı

|

HUATEC

|

2

|

PC

|

|

08

|

Akım trafosu

|

DELIXI

|

2

|

PC

|

|

09

|

tristör

|

DELIXI

|

2

|

SET

|

|

10

|

Hızlı erime

|

DELIXI

|

2

|

PC

|

|

11

|

Çevresel manyetize ana transformatör

|

HUATEC

|

1

|

PC

|

|

12

|

Boyuna manyetize ana transformatör

|

HUATEC

|

1

|

PC

|

|

13

|

LED El Tipi UV lambası

|

HUATEC

|

1

|

PC

|

|

14

|

LED Asılı UV lambası

|

HUATEC

|

1

|

PC

|

|

Yukarıdaki yedek parça üreticisi özellikleri sadece referans içindir ve kullanıcı gereksinimlerine ve stoktaki yedek parçalara göre ayarlanacaktır.

|

5. Cihaz açıklaması

5.1 Elektrik kontrol sistemi

Kontrol sistemi, iki elektrotun ve manyetizasyon demanyetizasyon cihazının çalışmasını kontrol eden programlanabilir lojik kontrolör (PLC) tabanlıdır. Ana gövde olarak kontrol kabini ile çeşitli yürütme bileşenleri, manyetizasyon tetikleme devresi, ana transformatör vb. içerir.

Dokunmatik ekran aracılığıyla manyetize edici akım ve diğer parametreleri girin. Manyetizasyon akımı ön ayar işlevini gerçekleştirmek için PLC analog giriş/çıkış modülü ile.

Çatlak bulma ana bilgisayarının tüm göstergeleri, düğmeleri ve çalışma ışıkları 24V güvenlik voltajını benimser.

Çatlak bulma ana bilgisayarı, demanyetizatör ve dağıtım kabini kabuğu güvenilir bir şekilde topraklanmıştır.

5.2 Ana bilgisayar

Ana makine: gövde, paslanmaz çelik toplama tankı, manyetizatör, püskürtme sistemi.

Gövde: Gövde yüksek kaliteli malzeme ile kaynaklanmıştır, güçlü ve güzeldir. Operatörün gövde etrafındaki yükseklik aralığında belirgin keskin açı yapısı yoktur.

Paslanmaz Çelik Toplama tankı: Manyetik süspansiyon toplama için yüksek kaliteli paslanmaz çelikten yapılmıştır.

Manyetizatör: sıkıştırma mekanizması, manyetize edici elektrot ve manyetize edici bobinden oluşur. Manyetize edici elektrot, iş parçasını çevresel olarak manyetize eder ve manyetize edici bobin, onu boyuna manyetize eder. Bobin ve elektrot plakası yüksek kaliteli bakırdan yapılmıştır. Sıkıştırma mekanizması pnömatik bileşenler tarafından tahrik edilir ve iş parçası, çevresel bir manyetize edici devre oluşturmak için iki elektrot arasına sıkıştırılır.

5.3 Manyetik süspansiyon püskürtme sistemi

Manyetik süspansiyon toplama tankı, su pompası, boru hattı ve sprinkler başlığından oluşur. Toplama tankı, geri dönüş manyetik süspansiyonu nozüle toplamak, karıştırmak ve pompalamaktan sorumludur. Sıvı toplama tankı haricidir ve tabanına fren cihazlı evrensel tekerlek takılmıştır. Ana motorun manyetik süspansiyon toplama tankı, gözlem platformu ve demanyetize konveyör bandı, damlamayı önlemek için sıvı toplama tankına geri kazanılır.

Mesajınız 20-3.000 karakter arasında olmalıdır!

Mesajınız 20-3.000 karakter arasında olmalıdır! Lütfen emailinizi kontrol edin!

Lütfen emailinizi kontrol edin!  Mesajınız 20-3.000 karakter arasında olmalıdır!

Mesajınız 20-3.000 karakter arasında olmalıdır! Lütfen emailinizi kontrol edin!

Lütfen emailinizi kontrol edin!