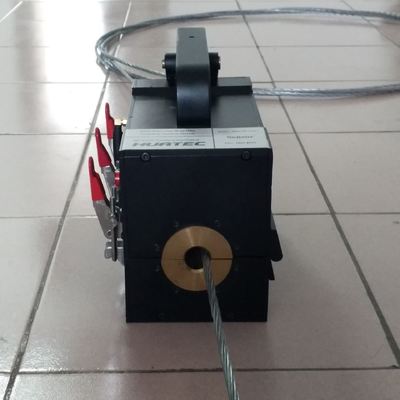

HRD-120 Entegre tel halat hatası tespit makinesi

一Ürün genel bakışı

◆Kablo ipi iç ve dış kırık kablo, aşınma, pas, deformasyon, gevşek iplik, sıçrama kablo, malzeme değişiklikleri ve diğer kusurların çevrimiçi tespiti.

◆Test sonucu raporu farklı endüstrilerin standartlarını karşılayabilir ve kırık tellerin sayısını ve kırık tel alanının telin toplam kırık alanına oranını içerir.

◆Bilgisayar USB arayüzünün (kableli) veya "kendi Wi-Fi ağının" (kablesiz) kullanımı, çevrimiçi ses ve ışık alarmı ve gerçek zamanlı görüntüleme sonuçları ile doğrudan örnekleme işleme analizi.

◆Sensör yuvarlak yapısı, çevresel çevre, eksenel manyetizasyon, tel ipi anlık manyetizasyon doymak durumuna.

◆Sensör, su geçirmez, toz geçirmez, şok geçirmez ve nem geçirmez işlevlere sahip alaşımlı alüminyum kabuk kullanır.

◆Istikrarlı çalışma, güvenilir performans, yüksek algılama doğruluğu, güçlü müdahale karşıtı performans, doğru veriler.

◆Yazılım Windows 98/2000 / xp/Vista/ Windows 7/8/10/11 çeşitli bilgisayar işletim sistemlerine uyarlanır

◆Madencilik, teleferik, kaldırma ekipmanları, asansör, liman makineleri, kablo köprüsü ve diğer alanlarda yaygın olarak kullanılır.

二- Teknik temel ve hukuki yeterlilik

1Sanal enstrüman: ip sonsuz belirsizlik. Sadece sanal enstrüman teknolojisinin uygulanması, geleneksel enstrümanları yazılımla değiştirmek,ve bilgisayarlar tarafından doğrudan örnekleme işleme hiçbir kaçırılmış tespit ve hiçbir yanlış yargılama sağlayabilirTıpkı bir filmi izlemek gibi, işlem boyunca tel ipi taramak, sonuçlar doğru ve iyi tekrarlanabilir.

2. Üç sabit alet: Farklı endüstrilerde tel halatı hurdaya yönelik ulusal standartlara göre, bu ürün elektromanyetik kalitatif, nicel, konumlandırma,Kablo ipi iç ve dış kırık telin çevrimiçi yıkıcı olmayan tespiti, pas, aşınma, metal kesim alanı değişiklikleri, gevşek iplikler, sıçrama tel, deformasyon, malzeme anomalileri ve diğer kusurlar.

3. Hukuki araç: ASTM1571-2021 Amerikan standardı ve GB/T21387-2008 ulusal standardına uygun.

三. Teknik göstergeler

Tüm serisi tel halat çapı aralığını tespit edebilir: φ1.5-300mm (farklı spesifikasyonlar sensör serisi yapılandırmak gerekir)

Algılayıcı ve tel ipinin göreceli hızı: 0.0-6.0 m/s En iyi: 0.1-0.5 m/s

Sensör rehber koltuk ve tel ipi arasındaki en iyi boşluk 2-4 mm ve izin verilen boşluk 0-15mm

Kırık tel hatasını tespit etme yeteneği (LF)

Niteliksel: Tek merkezi kırık telin niteliksel tespitinin doğruluğu% 99.99'dur

Kütleleri: Tek bir yerde kırık tellerin sayısı, bir veya bir eşdeğer kökenin yanlış yargılanmasına izin verir

Tek bir yerde kırık tel sayısının 100'den fazla kez hata yapmadan tespit edildiğinde doğruluk oranı% 92'den fazladır

Metal kesimin (LMA) miktarsal değişim oranı

Algılama hassasiyetinin izin verilen tekrarlanabilirlik hatası ±0,055%'dir.

Test hassasiyeti göstergesi değerinin izin verilen hatası: ± 0,2%

Pozisyon (L) Bulma yeteneği: Bulma uzunluğu göstergesi değerinin yüzde hata: ±0,2%

Güç kaynağı: Bilgisayar pilinden 5V

Sensör ağırlığı: ortak özellikler < 10kg (gerçek duruma göre özelleştirilmiş)

Çevre sıcaklığı: -10°C~ 40°CAtmosfer basıncı: 86 ~ 106Kpa Nitelik nem:≤% 85

四Sistem konfigürasyonu ve modeli

Hepsinin özelleştirilmesi gerekiyor: Tel ip kusur tespit makinesi (48mm küçük - 78mm orta - 108mm büyük)

|

|

SN.

|

Adı ve modeli yapılandır

|

miktarı

|

Mark

|

|

Algılama birimi

|

1

|

• Entegre algılama ünitesi

• Yüksek hızlı geri dönüştürülebilir uyarıcı • Yüksek iletkenlik sinyali konsantratörü

• Göster Hall manyetik duyarlılık grubu • Yüzen merkezli giyim kılavuzu koltuğu

• Yüksek hassasiyetli mesafe kodlayıcısı • Otomatik konumlandırma tekerlek yuvarlama cihazı

|

1bir dizi

|

Kodlayıcı dahil

|

|

2

|

• Gerçek zamanlı alarm (dijital analog dönüşüm hi-fi)

•AD analog-dijital dönüşüm modülü • Otomatik gürültü reddetme modülü

• Hasar sesli ve görsel alarm modülü • Algılama kalite güvence modülü

•DAQ plug and play modu

|

1bir dizi

|

Wi-Fi yakalama dahil

|

|

|

3

|

Değiştirilebilir astar

|

5 set

|

Özel özellikler ayrı olarak tartışılır.

|

|

İşleme birimi

|

4

|

USB iletim kablosu

|

% 1

|

Özel yapımı 20 metre uzunluğunda

|

|

5

|

Wi-Fi anteni

|

2 adet

|

Bir tanesi yedek parçalar için.

|

|

6

|

V3.0 sürümü gerçek zamanlı sinyal işleme yazılımı

|

1 set

|

|

|

7

|

Veri toplama Bilgisayarı (Tablet türü)

|

1 birim

|

Şarj cihazı dahil

|

|

Aksesuar birimi

|

8

|

Özel alet kılıfı

|

% 1

|

Özel çekme çubuğu vitesi

|

|

9

|

Hepsi birde şarj cihazı

|

% 1

|

Kırmızı ışık: Şarj

Yeşil: Tam

|

|

10

|

Esnek çekiş güvenlik kablosu

|

% 1

|

Algılama birimleri için esnek bağlantılar

|

|

11

|

Uygulama kılavuzu (özel teknik veriler)

|

% 1

|

|

|

12

|

Sertifika (Garanti kartı)

|

% 1

|

|

|

13

|

Paket listesi

|

% 1

|

|

Not: 1 adet, bunlardan 7 adet çift kullanımlı tablet bilgisayar isteğe bağlıdır (ilaca göre, maliyet ektir).

2, tüm boyutlar talep üzerine özelleştirilebilir (ve tam olarak özelleştirilebilir değiştirilebilir astar olabilir); 48mm + 24mm değiştirilebilir kabuğu gibi

Özel bir model:

Kullanım sitesi durumu:

|

|

Test, değerlendirme ve kabul

|

|

Li Jiacheng liman vincinin tespiti

|

|

|

|

|

Hong Kong asansör şirketi denetimi

|

|

Liman yeniden değerlendirmesi

|

|

|

Mesajınız 20-3.000 karakter arasında olmalıdır!

Mesajınız 20-3.000 karakter arasında olmalıdır! Lütfen emailinizi kontrol edin!

Lütfen emailinizi kontrol edin!  Mesajınız 20-3.000 karakter arasında olmalıdır!

Mesajınız 20-3.000 karakter arasında olmalıdır! Lütfen emailinizi kontrol edin!

Lütfen emailinizi kontrol edin!